- 25 Oct, 2016

- Control Systems

Project Description

Description - The KCS Silo Safety System for the safeguarding of silos consists of a central electronic monitoring and control unit which manages a series of silos and a component kit including, in the basic version one power panel for each silo, a silo pipe connection, a pinch valve, a tanker coupling with the filing pipe, a maximum level indicator, a differential pressure switch or electronic pressure meter, a pressure gauge for the venting filter, a pressure relief valve, and an audible alarm.

Function - The KCS Silo Safety System can be used for silos which are filled by tanker with powders or granular materials. Damage to the silo or its accessories is most likely during the operation of filling from tankers. This is due to the risk of overfilling or excess pressurisation. The KCS system, supplied in component form, prevents both overfilling and excess pressurisation, thus avoiding damage to the silo, to the venting filter or other accessories, and reducing the risk of dust emission into the atmosphere.

Performance & Technical Features - Benefits

- Avoids harm to people and damage to the silo and its accessories

- Reduces risk of air pollution

- Eliminates risk of filling the wrong silo

- Starts and stops filter cleaning automatically

- Electronic pressure meter gives indication of when the filter may need attention

- Internal pressure monitoring of each silo

- Maximum level indication

- Reveals presence of compressed air to venting filter (if air jet filter is used) and pinch valve

Options & Accessories

- Central control panel

- Individual power panel

- Pressure gauge

- Pressure relief valve VCP

- Audible alarm

- Tanker Coupling

- Venting Filter

- Pressure switch/differential pressure meter

- Spigot for pressure switch/meter

- Level indicator

- Pinch valve incl.pneumatic control panel

- 19 Oct, 2016

- Control Systems

Project Description

Description - The WAMFLO Dust collectors are equipped with a cylindrical shape stainless steel body with flanged connection that contains vertically mounted POLYPLEAT filter elements. The air jet cleaning system is integrated in the top cover. WAMFLO Dust Collectors are available with or without suction fan.

Function - WAMFLO Dust Collectors are used for both venting and suction applications. The modular system combines the maximum safety of a flanged body connection with the variety of options in terms of type of filter media and filtering elements with the unique integrated pneumatic cleaning system design.

Performance & Technical Features - Benefits

- 304 stainless steel flanged cylindrical shape body

- Filter surface from 1 to 48m2 (11 to 517sq ft)

- Air volume from 60 to 4,500m3/h (35 to 2,650 cfm)

- Low emission level due to B.I.A.-certified filter media

- High filtration efficiency thanks to unique WAM filtering elements

- Easy maintenance due to particularly quick access to the filtering element removal

- Multifunctional intelligent electronic control panel

- Filter elements: Round bags, elliptical bags, cartridges, POLYPLEAT

- Comfortable maintenance height

- Compressed air jet cleaning system integrated in top cover

- High cleaning efficiency due to "Full Immersion" solenoid valves incorporated in aluminium air tank (corrosion-resistant) for low-on-maintenance operation

- Safe weather protection cover with lockable snap hook

- No tools for filtering element removal required

- Increased durability

- Reduced maintenance costs

- Hygienic operation

- Increased work safety

- Lower operating costs

- Exceptional price-quality ratio

Versions Available

- WAMFLO S-type:

BASIC filters for pressure and suction systems - WAMFLO I-type:

INSERTABLE filters for pressure and suction systems - WAMFLO D-type:

NEGATIVE PRESSURE application filters - WAMFLO E-type:

INSERTABLE NEGATIVE PRESSURE application filters - ATEX VERSIONS AVAILABLE UNDER THE NAME WAMFLO ATEX

Options & Accessories

- Suction fan

- Connection for centralised suction

- Electronic differential pressure meter (MDPE)

- WAMFLO Front: with large access door for removal of filter elements from dirty side

- Dust collection hopper with bucket, butterfly valve or rotary valve, and flow aids

- Winter protection for solenoid valves

- 19 Oct, 2016

- Control Systems

Project Description

Description - The WAMAIR Dust Collectors consist of a polygonal shape 304 stainless steel casing, horizontally or vertically inserted filter elements, and a reverse air jet cleaning system integrated in the hinged access door. WAMAIR Dust collectors are either built in for venting applications or come as a stand-alone unit with dusting hopper. For suction, versions with an integrated fan are available.

Function - WAMAIR Dust Collectors separate dust from the air flow by means of pocket or special POLYPLEAT filter elements. Dust drops down after an automatic reverse air jet cleaning device inside the front inspection door has removed it from the filter elements. The dirty air flow may enter the filter casing from the top inlet flange where heavier particles are subsequently pre-separated while the flow is on the descent. Alternatively, dirty air may enter from the bottom flange which can be connected to a WAM PT-type hopper or to the device to be de-dusted (silo, belt conveyor, bucket elevator, chain conveyor etc).

A special ATEX-version for zone 22 (Category 3D equipment) is available.

Performance & Technical Features - Benefits

- High quality compact 304 stainless steel body

- Filter surface: 3 to 70m2 (32 to 755 ft2)

- Air volume from 250 to 6,500m3/h (147 to 3,830 cfm)

- High filtration efficiency thanks to high range of B.I.A.- rated filter media

- Multi-functional electronic control panel installed in standard version with end of cycle cleaning system

- Dust collectors can be easily turned into food-grade version

- Standard equipment developed for temperature range from -20 degree C to 80 degree C (-4F to 176 degree F)

- ATEX 94/9/EC version available for zone 22 (equipment category 3D)

- ATEX reduced pressure PRED = 0.25 barg

- Standard explosion relief panel by REMBE

- Easy installation, filter delivered in one piece

- Reverse air jet cleaning system integrated inside access door for easy maintenance

- Quick filter element removal from clean air side for easy maintenance

- High cleaning efficiency due to "Full Immersion" solenoid valves incorporated in aluminium corrosion-resistant air tank

- Silenced fan range integrated in access door reduces operating noise level

Versions Available

- FPH-type: horizontal collectors

- FPV-type: vertical collectors

- FPI-type: horizontal insertable collectors

- FPE-type: vertical insertable collectors

Options & Accessories

- Wide fan range for suction applications

- Spigot for centralised suction

- Dust collection hopper with bucket, butterfly valve, rotary valve, and various types of flow aids

- Electronic differential pressure meter

- Winter protection for solenoid valves

- 19 Oct, 2016

- Control Systems

Project Description

Description - The WAMAIR Dust Collectors consist of a polygonal shape 304 stainless steel casing, horizontally or vertically inserted filter elements, and a reverse air jet cleaning system integrated in the hinged access door. WAMAIR Dust collectors are either built in for venting applications or come as a stand-alone unit with dusting hopper. For suction, versions with an integrated fan are available.

Function - WAMAIR Dust Collectors separate dust from the air flow by means of pocket or special POLYPLEAT filter elements. Dust drops down after an automatic reverse air jet cleaning device inside the front inspection door has removed it from the filter elements. The dirty air flow may enter the filter casing from the top inlet flange where heavier particles are subsequently pre-separated while the flow is on the descent. Alternatively, dirty air may enter from the bottom flange which can be connected to a WAM PT-type hopper or to the device to be de-dusted (silo, belt conveyor, bucket elevator, chain conveyor etc).

A special ATEX-version for zone 22 (Category 3D equipment) is available.

Performance & Technical Features - Benefits

- High quality compact 304 stainless steel body

- Filter surface: 3 to 70m2 (32 to 755 ft2)

- Air volume from 250 to 6,500m3/h (147 to 3,830 cfm)

- High filtration efficiency thanks to high range of B.I.A.- rated filter media

- Multi-functional electronic control panel installed in standard version with end of cycle cleaning system

- Dust collectors can be easily turned into food-grade version

- Standard equipment developed for temperature range from -20 degree C to 80 degree C (-4F to 176 degree F)

- ATEX 94/9/EC version available for zone 22 (equipment category 3D)

- ATEX reduced pressure PRED = 0.25 barg

- Standard explosion relief panel by REMBE

- Easy installation, filter delivered in one piece

- Reverse air jet cleaning system integrated inside access door for easy maintenance

- Quick filter element removal from clean air side for easy maintenance

- High cleaning efficiency due to "Full Immersion" solenoid valves incorporated in aluminium corrosion-resistant air tank

- Silenced fan range integrated in access door reduces operating noise level

Versions Available

- FPH-type: horizontal collectors

- FPV-type: vertical collectors

- FPI-type: horizontal insertable collectors

- FPE-type: vertical insertable collectors

Options & Accessories

- Wide fan range for suction applications

- Spigot for centralised suction

- Dust collection hopper with bucket, butterfly valve, rotary valve, and various types of flow aids

- Electronic differential pressure meter

- Winter protection for solenoid valves

- 19 Oct, 2016

- Control Systems

Project Description

Description - The SILOTOP is a cylindrically shaped dust collector for venting of pneumatically filled silos. The stainless steel body contains vertically mounted, POLYPLEAT filter elements. The air jet cleaning system is integrated in the hinged weather protection cover.

Function - Dust separated from the air flow by special POLYPLEAT filter elements drops back into the silo after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed it from the filter elements.

Performance & Technical Features - Benefits

- Compact 800mm (30 in) diameter 304 stainless steel body with bottom flange 24.5m2 (264 sq ft) filter surface

- Maintenance height = 1,100mm (3.6ft)

- High filtration efficiency due to POLYPLEAT filtering elements

- Low dust emission level due to B.I.A. - certified filter media

- Maintenance-free air jet cleaning unit integrated inside weather protection cover

- Safe weather protection cover with lockable snap hook

- No tools required for filtering element removal

- Robust design

- Perfectly accessible due to compact design

- Complete replacement of filter media by only one person within a few minutes.

Options & Accessories

- Weld-on bottom ring

- Multifunctional electronic differential pressure meter

- Winter protection for solenoid valves

- 19 Oct, 2016

- Control Systems

Project Description

Description - The HOPPERJET is a small footprint venting filter for installation on intermediate storage hoppers or weigh hoppers.

Function - The HOPPERJET is a compact venting filter for mechanically filled hoppers. Dust which is separated from the air flow by a single POLYPLEAT or bag-type filter element drops back into the hopper after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed the dust particles from the filter elements.

Performance & Technical Features - Benefits

- 304 stainless steel flanged body

- Low emission level due to B.I.A. - certified filter media

- Special design compressed air jet cleaning system

- High filtration efficiency due to unique WAM design filter elements

- Quick maintenance due to easy access for filtering element removal

- Maintenance-free air jet cleaning unit integrated inside weather protection cover

- High cleaning efficiency due to "Full-Immersion" solenoid valves incorporated in corrosion-resistant aluminium air tank

- No tools required for filtering element removal

- Minimum maintenance required

- High efficiency

- Minimum space required

- Easy to fit and retrofit

Options & Accessories

- Spigot for centralised suction system

- Electronic differential pressure meter (MDPE)

- 304 or 316 stainless steel cover

- 316 stainless steel body

- 19 Oct, 2016

- Control Systems

Project Description

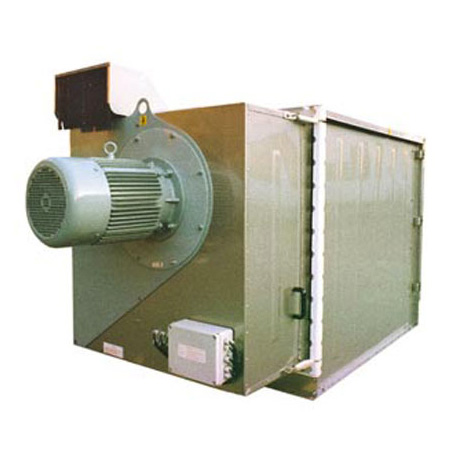

Description - The polygonal shape DRYBATCH Dust Collector is equipped with horizontally mounted filter elements, a compressed air jet cleaning system integrated in the access door and a suction fan.

Function - The DRYBATCH Dust Collector has been specially designed for dust collection from the truck mixer inlet zone in dry batch plants during filling of the truck mixer.

Performance & Technical Features - Benefits

- 304 stainless steel body

- Exceptional volume-filter surface ratio

- Filter surface: 45 / 58 / 70 m2 (480 / 620 / 750 sq ft)

- Maintenance-free air jet cleaning system inside maintenance access door

- High cleaning efficiency due to "Full Immersion" solenoid valves incorporated in aluminium corrosion-resistant air tank for low-maintenance operation

- High filtration efficiency thanks to WAM filtering elements

- Multi-functional electronic control panel included in standard version

- Diffuser for pre-separation of heavier particles and moisture elimination

- Easy installation

- Space-saving compact design

- Filter can be fitted in new and existing plants

- Extremely maintenance-friendly (no ladders, no scaffolding)

- Particularly durable filter media

- Silenced WAM fan range reduces operating noise by approximately 10 Db(A) compared to other makes

- Low dust emission

Options & Accessories

- Dust collection hopper with bucket, butterfly valve, rotary valve, and/or various types of flow aids

- Multifunctional electronic differential pressure meter

- Winter protection for solenoid valves

- 13 Oct, 2016

- Control Systems

Project Description

We offer a comprehensive Dust Collector range for de-dusting and dust control for virtually all industrial applications. Polygonal dust collectors with shaker cleaning, insertable polygonal dust collectors for negative pressure, clamped round dust collectors, weigh hopper venting filters and the following dust collectors linked below;

Dust Collectors